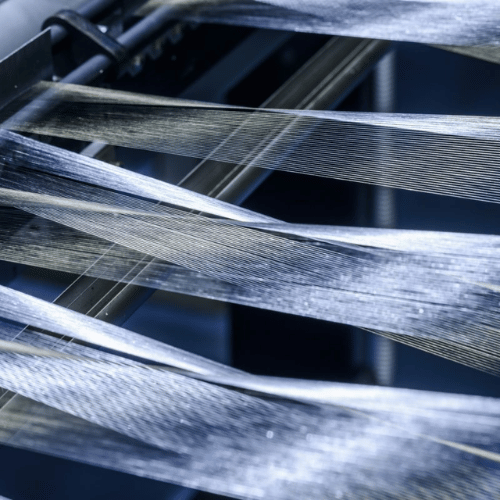

Nylon a synthetic material that has been used in many industries for decades. It’s lightweight, durable and versatile.

But what are the advantages and disadvantages of using nylon?

Nylon is popular among manufacturers due to its strength and flexibility. It’s also relatively inexpensive compared to other materials, making it an attractive option for budget-conscious shoppers. Furthermore, nylon is water-resistant, making it a great choice for outdoor clothing and accessories.

However, nylon also has some drawbacks. It’s not as breathable as natural fabrics such as cotton or wool, making it less comfortable in hot climates. Additionally, nylon is more difficult to dye than other fabrics, which limits its color options. Finally, some people may find the texture of nylon uncomfortable against their skin.

In this article, we’ll explore the pros and cons of this man-made fabric, and how it can be used to our advantage.

Uses And Applications

Nylon’s versatility makes it an ideal choice for many uses. Its strength and durability make it a great choice for everyday items like clothing, rope, and even parachutes.

It can also be used in industrial applications such as conveyor belts and other heavy-duty machinery. Here are some of the most common uses for nylon:

- Clothing: Nylon is often used to make clothing that is lightweight yet strong and durable. From socks to raincoats, this material provides protection from the elements while remaining comfortable to wear.

- Rope: Nylon is incredibly strong and resistant to stretching, making it a great choice for rope. Because of its properties, it’s often used in many different areas including climbing ropes and fishing lines.

- Parachutes: Nylon’s strength makes it ideal for use in parachutes. Not only does the fabric provide a secure attachment point, but its lightweight nature also helps keep the wearer safe during their descent.

- Industrial Applications: The strength of nylon makes it perfect for use in industrial applications such as conveyor belts and other heavy-duty machinery. Its ability to resist wear and tear makes it an ideal choice for these types of applications.

- Automotive Parts: Nylon can also be found in automotive parts such as fan belts, timing belts, and fuel lines due to its ability to withstand heat and extreme temperatures.

In short, nylon has proven itself over time due to its wide variety of uses both big and small.

Its unique combination of strength and flexibility make it one of the most versatile materials on the market today which is why it’s so widely used in nearly every industry imaginable.

With this in mind, let’s take a closer look at how durable nylon really is…

Durability

Nylon’s durability is one of its most desirable characteristics. The fabric can withstand wear and tear, as well as extreme temperatures, making it suitable for a variety of applications.

It also has low moisture absorption, which helps to keep the material from becoming stiff or brittle over time.

These properties make nylon an ideal choice for items such as clothing, rope, parachutes, and industrial machinery that require long-term use.

In addition to its remarkable durability, nylon is also incredibly strong and resistant to stretching.

This makes it perfect for uses such as climbing ropes or fishing lines where strength is essential. Its lightweight nature also gives it an advantage in parachute manufacturing where weight is a key factor in the design.

In short, nylon’s unique combination of properties make it a great choice for any application that requires both strength and flexibility.

Strength And Flexibility

Nylon is a highly versatile material that offers strength and flexibility in equal measure.

Its high tensile strength makes it an excellent choice for use in items such as climbing ropes or fishing lines, while its low-stretch properties make it perfect for parachute manufacturing.

On top of this, nylon’s light weight allows for greater maneuverability and control.

These impressive qualities make nylon a great choice for any application that demands both strength and flexibility.

Moreover, its resistance to abrasion, heat and chemicals make it an ideal fabric for industrial applications.

Nylon can withstand temperatures of up to 140°C without melting, making it suitable for use in products like electrical insulation and protective clothing.

It also has the ability to resist acidic and alkaline solutions, making it suitable for laboratory use.

All these benefits come with drawbacks too; nylon is not biodegradable or sustainable which means it takes longer to decompose than natural fabrics such as cotton or wool.

Additionally, nylon has poor breathability which means that clothes made from nylon can cause discomfort due to its inability to absorb moisture.

Despite these limitations, nylon remains a popular choice due to its impressive combination of features.

Cost Effectiveness

Nylon’s cost effectiveness makes it a desirable material for many applications. Its low price point and durability make it an attractive option for manufacturers who need a reliable product that won’t break the bank.

On top of this, nylon is easy to dye and manipulate into different shapes, allowing for further customisation and cost savings.

It can also be used in combination with other materials such as cotton to create interesting new textures and finishes.

What’s more, nylon is less prone to damage than natural fabrics like wool or silk.

This means that items made from nylon are likely to last longer than those made from these other materials, making them an even better value for money proposition.

Additionally, its strength gives it the ability to hold up against everyday wear and tear without showing signs of distress.

All this makes nylon an ideal choice for items such as camping gear or sports clothing as its long-lasting durability ensures that you won’t have to replace your items too often.

Plus, its affordability means that you can still get quality items without spending too much money.

Sensitivity To Heat

Nylon’s sensitivity to heat can be a major issue for manufacturers. Studies show that the material can start to degrade at temperatures as low as 104°F (40°C).

This means that if it is exposed to extreme heat or sunlight, it will quickly become weak and brittle.

Additionally, nylon’s strength also decreases when exposed to moisture, making it unsuitable for applications such as umbrellas or outdoor furniture.

Here are three key points about nylon’s sensitivity to heat:

- Nylon can start to degrade at temperatures as low as 104°F (40°C).

- When exposed to extreme heat or sunlight, nylon quickly becomes weak and brittle.

- Its strength decreases when exposed to moisture, making it unsuitable for certain applications.

These issues mean that nylon is not suitable for items which need to withstand high temperatures or exposure to the elements over long periods of time.

Therefore, extra care must be taken when choosing nylon-based products in order to ensure they remain in good condition and work properly when needed.

Environmental Impact

Given its sensitivity to heat and moisture, nylon is not the most environmentally friendly material. It is derived from petroleum, so it has a large carbon footprint when produced.

In addition, manufacturing processes also release harmful chemicals into the atmosphere.

This can have a negative impact on local ecosystems and can contribute to global climate change.

However, there are some measures that manufacturers can take to reduce their environmental impact.

For instance, they can use recycled materials in their production process or switch to more sustainable energy sources for their operations.

They can also implement more efficient waste management systems to reduce the amount of plastic waste generated by production processes.

In some cases, manufacturers may even be able to convert their used nylon materials into new products or find other ways to reuse them.

Fortunately, these efforts could help make nylon a more sustainable option for many applications without sacrificing its strength or durability.

Chemical Corrosion Resistance

Another benefit of nylon is its chemical corrosion resistance.

This makes it a great choice for applications where exposure to harsh chemicals or abrasive materials is a concern. Here are four reasons why nylon stands out in this regard:

- Its strong molecular structure means it can tolerate long-term contact with harsh chemicals without breaking down.

- It won’t rust or corrode, even when exposed to water or high levels of humidity.

- Its unique polymer structure allows it to resist abrasion and wear better than many other materials.

- It has excellent dimensional stability, so it won’t shrink or expand when exposed to changes in temperature or humidity.

Overall, nylon is highly resistant to chemical corrosion, making it an ideal choice for many industrial and manufacturing applications.

As such, it can provide a more durable solution than traditional materials like metal or wood in these types of situations. And with proper care and maintenance, its chemical corrosion resistance could last for years.

With that said, let’s move on to discuss the flame retardant properties of nylon.

Flame Retardant Properties

Nylon’s flame retardant properties make it a popular choice for many applications.

This is because it has the ability to resist burning and melting even when exposed to high temperatures or open flames. Here’s how nylon stands out in this regard:

- Its chemical structure gives it an inherently fire resistant quality that many other materials lack.

- It won’t easily ignite or melt, so it can provide reliable protection in areas prone to fire hazards.

- Its low melting point means it won’t give off toxic fumes when exposed to extreme heat.

Overall, nylon provides excellent flame retardant qualities, making it an ideal choice for a variety of uses where fire safety is a priority.

Types Of Nylon

Nylon is available in several different forms, each with their own advantages and disadvantages.

Nylon 66 is the most common type, offering good strength and resilience. It’s also very durable, so it can withstand wear and tear over time without stretching or sagging. However, it doesn’t have any flame retardant properties, and it’s not as lightweight as other types of nylon.

Nylon 6 offers excellent flexibility and resistance to wear and tear. This makes it ideal for items that need to flex or bend frequently. It also has better flame retardant properties than Nylon 66. On the downside, it’s not as strong or durable as some other types of nylon.

Nylon 12 is the most heat resistant type of nylon, making it suitable for applications that require high temperatures. Its high melting point means it won’t melt even when exposed to extreme heat sources like open flames. But this same quality makes it less flexible than other nylons.

Overall, each type of nylon has its own unique set of advantages and disadvantages which should be taken into account before making a purchase decision.

Frequently Asked Questions

How Does Nylon Compare To Other Fabrics In Terms Of Comfort?

Nylon is a common fabric choice when it comes to clothing. But how does it compare to other fabrics in terms of comfort? Well, nylon has some distinct advantages that make it a great choice.

It’s lightweight and strong, making it easy to wear and durable enough to withstand daily wear and tear.

Additionally, because of its high water absorption capacity, nylon is naturally breathable and can help keep you cool in warm temperatures.

On the other hand, there are some drawbacks with nylon. It’s not as soft or comfortable as other fabrics like cotton or wool, so if you’re looking for a fabric that will feel soft against your skin, then you may want to look elsewhere.

Furthermore, if you’re looking for a fabric that won’t wrinkle easily or show signs of wear-and-tear quickly, then nylon might not be the best choice either.

Overall, nylon is a great choice for many reasons but keep in mind its limitations when it comes to comfort and durability. If these two factors are important to you when choosing clothing materials then you may want to consider fabrics like cotton or wool instead of nylon.

What Is The Most Common Form Of Nylon?

Nylon is a versatile fabric, used in everything from clothing to parachutes. It’s often seen as the go-to material for strength and durability. But what is the most common form of nylon? Like a diamond in the rough, it can be hard to identify at first.

As with any material, there are pros and cons to using nylon: it’s lightweight yet strong; it can be dyed easily, but it’s also prone to pilling. But even then, its versatility makes it a great choice for all sorts of applications – from fashion to furniture upholstery. Here are four reasons why nylon is so popular:

1. It’s durable and long-lasting – Nylon has excellent tensile strength and tear resistance, making it one of the most resilient fabrics around.

2. It’s easy to clean – Nylon retains its color and shape through many washings, meaning you don’t have to worry about losing your favorite pieces over time.

3. It’s cost-effective – Due to its low cost, nylon is often used in place of more expensive materials like leather or wool.

4. It’s versatile – With nylon, you can make everything from apparel items like trousers and blazers to outdoor gear like tents and backpacks.

In short, nylon is an essential fabric for everyday use and industry alike. Its durability and cost-effectiveness make it a sound investment for anyone looking for quality materials that won’t break the bank.

How Is Nylon Affected By Prolonged Exposure To Sunlight?

Sunlight has an effect on nylon. It can weaken the fibers and make them brittle over time. To prevent this from happening, it’s important to limit the exposure of nylon to direct sunlight.

Nylon is susceptible to UV radiation, which means that too much sunlight can cause discoloration and fading of the material. This can reduce the overall quality of a product made with nylon, particularly if it’s used outdoors or in bright conditions.

To combat this, fabrics made with nylon should be treated with UV-resistant coatings or kept out of direct sunlight when possible.

Nylon is a versatile material that can be used for a variety of applications, but it needs special care when exposed to sunlight to ensure it lasts as long as possible.

Taking precautions such as treating fabrics with UV-resistant coatings and limiting exposure to direct sunlight will help preserve the integrity of products made with nylon.

Are There Any Health Risks Associated With Wearing Nylon Fabrics?

Wearing nylon fabrics can have its advantages, but it’s important to consider the potential risks. From potential health hazards to environmental concerns, there are many things to consider when wearing nylon fabrics.

It’s possible for nylon fabrics to cause skin irritation and discomfort due to their synthetic nature. Nylon fibers can trap heat and moisture which could lead to rashes, itching, and other issues.

Some people may be more sensitive than others and could have an allergic reaction from contact with nylon fabric.

Nylon is also a petroleum-based product made from nonrenewable resources.

The production of this type of fabric requires large amounts of energy and water which can contribute to climate change and pollution in some areas.

It’s important to be aware of the environmental impact of choosing nylon as a clothing or accessory material.

The decision to wear nylon should take all these factors into account before doing so.

Even if there are benefits associated with wearing this type of fabric, it’s still important to weigh the risks carefully before making a final decision.